What’s a Rich Text element?

The rich text element allows you to create and format headings, paragraphs, blockquotes, images, and video all in one place instead of having to add and format them individually. Just double-click and easily create content.

Static and dynamic content editing

A rich text element can be used with static or dynamic content. For static content, just drop it into any page and begin editing. For dynamic content, add a rich text field to any collection and then connect a rich text element to that field in the settings panel. Voila!

How to customize formatting for each rich text

Headings, paragraphs, blockquotes, figures, images, and figure captions can all be styled after a class is added to the rich text element using the "When inside of" nested selector system.

- This is it.

Silico has helped a customer-facing business unit of a large European telecom with several hundred million in revenue. Using the power of Business Process Simulation (BPS), Silico helped improve the unit’s struggling order management process after hitting a wall with process mining. By leveraging Silico’s BPS platform, the company identified process improvements that unlocked £37m in additional profit and dramatically improved lead times and customer satisfaction linked to their order-to-cash process.

Getting a struggling delivery process back on track

The business unit experienced a significant decrease in delivery process performance from July 2022 to early 2023. Customers faced longer lead times, resulting in a 10% drop in net promoter score (NPS) and a surge in negative feedback on comparison sites. As backlogs in the process increased, orders with a value of about £15 million were stuck in the process, resulting in delayed and lost revenue.

It was vital for the business unit to transform the process to improve customer satisfaction, increase revenue, and ensure the process was fit for the uncertain economic environment, including a reduction in FTE capacity of about 10%. The transformation team was given an impossible task: to get KPIs back on track while allowing the business to reduce headcount.

When process mining actions fail

The transformation team used process mining to understand their as-is process and identify potential bottlenecks. Process mining provided a valuable picture and analytics of their current order management process.

The transformation team acted on the most significant, actionable ‘undesirable activity’ identified through process mining: eliminating the delivery blocks. Nearly 130k orders (17%) exhibit delivery blocks after order confirmation. The team thought they could remove 80% of cases going through this activity by capturing information during the ordering journey better. They expected this would free up significant time with the delivery team, speeding up the processing of all orders. Additionally, it would remove four days of additional lead time for orders with delivery blocks.

However, the changes had little effect on the process and commercial KPIs, wasting tens of thousands of pounds and weeks of the transformation and IT teams’ time. The transformation team is now wondering how to get the process back on track and achieve targets for their stakeholders.

Silico helps customers go from mining to value and action in just four weeks

Silico enabled the company to move from process mining to action in a proof-of-value over just four weeks through the following steps:

- Importing the process mining graph and analytics to develop a Digital Twin of the process.

- Adjusting and testing the Digital Twin to ensure insights can be trusted, and incorporating volume forecasting and financial analysis modules.

- Conducting forward-looking simulations to identify where issues will occur when FTE capacity is reduced to focus the transformation team’s efforts.

- Evaluating process changes that the team could implement straight away to prioritise changes and maximise the team’s impact on KPIs.

Focus the attention of the transformation team and avoid pitfalls of low-impact changes suggested by process mining

After creating a working Digital Twin of the process, Silico has simulated the impact of the headcount reduction. Reducing FTE capacity by 10% without any process changes would further deteriorate process performance, including backlogs, lead time, NPScore, revenue, and profit.

Silico can also test the change suggested by process mining. Considering the reduction in headcount, the change was insignificant in counteracting the lower capacity.

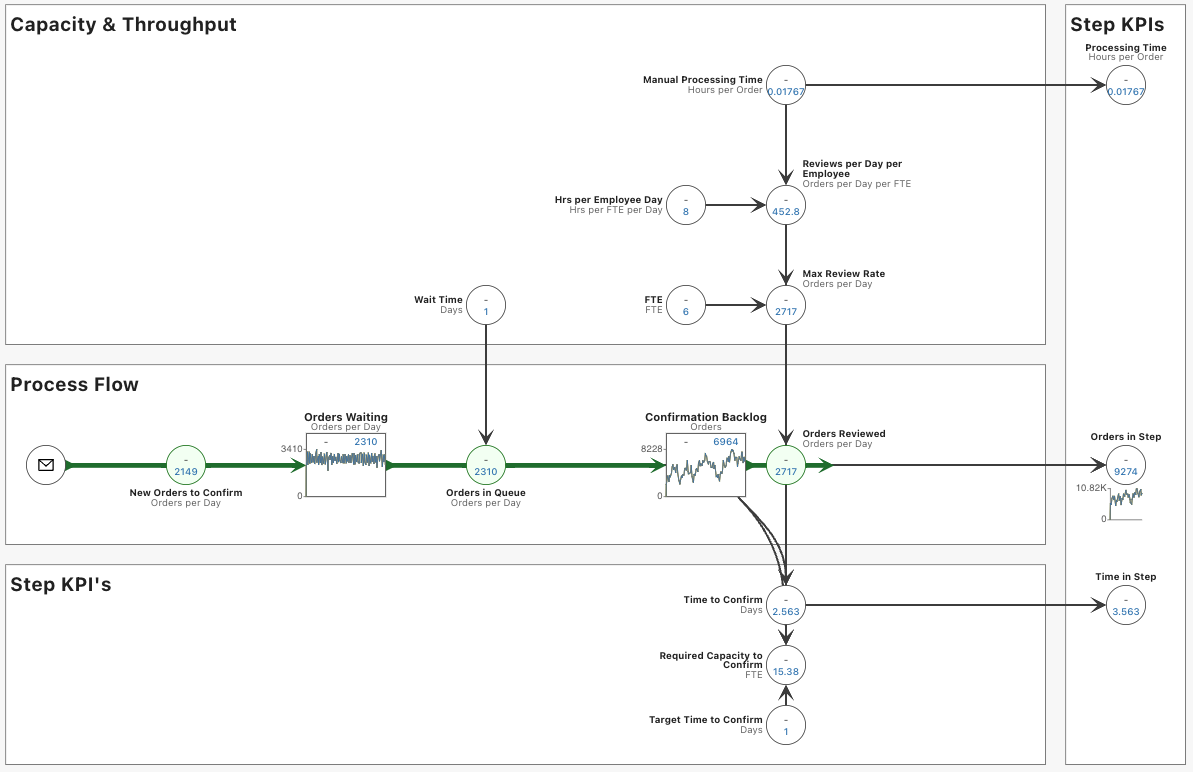

Our original simulation of the headcount reduction can tell the transformation team why the mining improvement has not worked and where transformation efforts need to focus. The modification suggested by process mining affects the team getting orders to the customer, which has the lowest backlog when capacity is reduced. Instead, an improvement should focus on the team reviewing and confirming orders, the first step of the process. If the transformation team had known this ahead of their change and simulated their process improvements, they could have saved valuable resources and budget on more impactful process changes.

Identify process improvements that unlock £37m in additional profit and that get lead times and customer satisfaction more than just back on track

With Silico, the transformation team could short-circuit the DMAIC cycle and quickly identify and implement impactful changes. They could use the Digital Twin to completely redesign the order confirmation process by designing and testing process variants that remove waiting time and introduce automation.

By exploring different process variants, the team identified improvements that resolved the issues in the order management process. They unlocked £37m in additional profit and significantly improved lead times and customer satisfaction by removing waiting times and automating process steps in a way that achieved the highest possible ROI.

Maximise the value of your process mining with simulation

Silico has proven invaluable for this Telco’s business unit looking to turbocharge its transformation team after process mining. By identifying changes missed by process mining and providing a forward-looking view of the process, Silico allows better decision-making that avoids pitfalls, focuses attention where it is required, and quantifies the impact of process changes on the commercial outcomes that matter for stakeholders - all to unlock millions in benefit for their business.

To read the full case study, and download as a PDF, click the button below.